|

Geology of Area

The Quarries

Picture Gallery

|

|

|

| |

Quarrying in and Around The RidgeThere are clues to suggest that quarrying has taken place at the Ridge for many centuries. In the Middle Ages, Chipping Sodbury was inhabited by a landowner known as Roger de Quarreria. Limekiln Lane runs along the Ridge. We know that small-scale activity took place at Yate Rocks and Bury Hill and that there was once a series of quarries all along the Wickwar-Chipping Sodbury Road. A very early quarry lay on land east of the area called Lilliput in Chipping Sodbury. This was filled in long ago, and the land now serves as school playing fields.

In 1805, “John Ball held the Nottles and Little Mead together with a lime kiln”. And in the 1842 edition of Kelly’s Directory, we discover that there were three lime-burners in Chipping Sodbury.

Barnhill Quarry

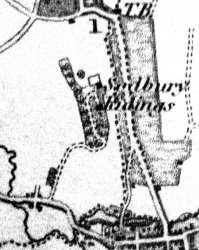

The tithe map of 1839 indicates a small quarry on The Ridge adjacent to Stub Riding, lying immediately within the Chipping Sodbury boundary.

From 1844, men at the nearby workhouse (now the Ridgewood Centre) were conscripted to work for the quarry. Their task was to break down the stones into pieces small enough to fit into their mouths, employing huge hammers and axes for this purpose. The stone was then used to build or mend local roads. Each man was expected to break several hundredweight of stones every day. From 1844, men at the nearby workhouse (now the Ridgewood Centre) were conscripted to work for the quarry. Their task was to break down the stones into pieces small enough to fit into their mouths, employing huge hammers and axes for this purpose. The stone was then used to build or mend local roads. Each man was expected to break several hundredweight of stones every day.

In 1859, records show that there was a limestone quarry on Barn Hill, together with a lime kiln. The quarry covered 11 acres, 2 rods and 7 perches and was owned by Isaac Limbrick and James Hancock. The former also owned some of the adjacent land. We learn about these quarry owners in an already-mentioned legal document presenting the case for altering the line of a footpath that ran through the fields and into Ridge Wood.

In 1862, there are indications of quarrying around the fringes of The Ridings and probably at Yate Rocks. From this point, it seems there was a path leading to a lime kiln, which lay next to the track of the Midland Railway. A siding connected the path to the track.

In 1882, amongst other lands, “The Roaches” was auctioned. This land lay just to the south of the Ridge, close to the Frome. It was described as offering a “warm early garden and a quarry of the finest limestone”.

By the late 19th century, the Barn Hill Quarry that we know today, in its position south of Love Lane, was being worked for the first time. The 19th century witnessed the demise of the pack horse and the mule train as the most efficient form of transport. In their place, came the railways. A huge quantity of stone was moved by means of the latter. By the 1920s, the railways were particularly busy. However, the stone still had to be taken to the railway line by horse-drawn cart. The 19th century witnessed the demise of the pack horse and the mule train as the most efficient form of transport. In their place, came the railways. A huge quantity of stone was moved by means of the latter. By the 1920s, the railways were particularly busy. However, the stone still had to be taken to the railway line by horse-drawn cart.

During the 20th century, quarrying became the dominant source of employment for the area. After the First World War, the demand for the limestone it produced greatly increased as the building of roads accelerated.

By 1929 a number of small companies in the West Country were merged to form The British Quarrying Company (later ARC), a forerunner of today's Hanson. The group included John Arnold Limited, a family business which ran the Chipping Sodbury quarry at Barnhill.

The quarry formed the headquarters for ARC who became the largest stone company in the world. Personnel were employed in Britain, Eire and North America.

Barnhill was quarried in the days when little thought was given to what was being left behind. It was finished in the mid-50s and for the last 40 years has lain empty. Barnhill Quarry is now designated as being of regional importance geologically. Of particular significance is a section of limestone pavement, which is recognised as a Site of Special Scientific Interest. Three applications have been made to fill the quarry with waste but all have been unsuccessful.

In 1977, a tunnel was constructed beneath Wickwar Road so that quarrying could begin at Hampstead Farm. In 1977, a tunnel was constructed beneath Wickwar Road so that quarrying could begin at Hampstead Farm.

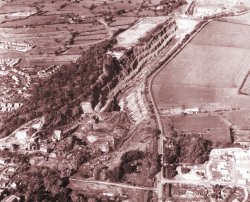

Barnhill Quarry remains as an enormous legacy to past industry - 3/4 of a mile long, 800 yards wide and (in places) 140 feet deep.

Chipping Sodbury QuarryChipping Sodbury quarry produces around 700,000 tonnes of limestone a year. It supplies construction materials to projects ranging from major motorway repair schemes to local building works. The 500 acre quarry sits on a ridge of limestone stretching north to Wickwar and Cromhall.

Today's quarrying operations are centred on Southfields, which is now fully worked out but houses all the stone processing machinery. The rock is dug at Hampstead Farm to the east of Wickwar Road.

The workings are moving towards Brinsham Stream to the north and the Ridings to the south-east and will continue for a further 15 years or so at current output rates.

The quarry will then move north into Brinsham Farm, starting on the eastern side, and progress west towards Yate Rocks. This area contains a further 30 years of reserves. A scheme of conditions outlining how the quarry will be worked over the next 40 years is being considered by South Gloucestershire planners.

In the last few years Hanson has invested over half a million pounds in environmental improvements to reduce dust and noise. This includes a computer-controlled dust suppression system on the stock piles at Barnhill, enclosed screening operations at Southfields and sprayers on the ends of every crushed rock conveyor belt.

Sprayers have also been installed alongside internal roads, which have been surfaced to keep dust down. There are wheel washes for trucks leaving the quarry and the stock piles and the quarry runs its own road sweeper and internal water bowser, which are both used daily.

Thanks to Hanson Aggregates for information and images

Return to top of page

|

|

| |

|